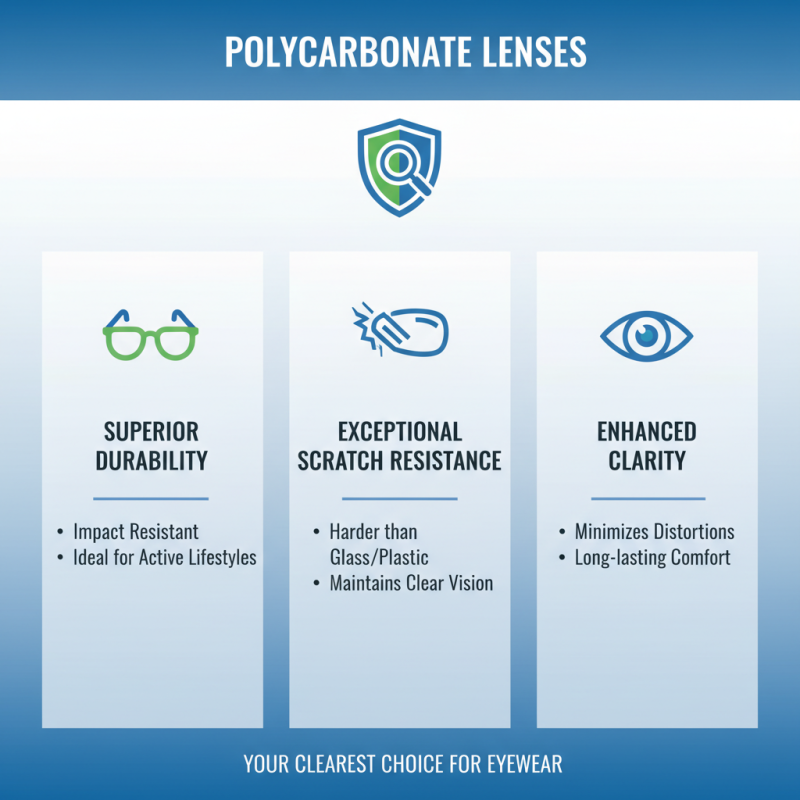

Polycarbonate lenses have become a popular choice for eyewear and safety gear. These lenses offer numerous advantages, making them suitable for various environments. Their lightweight design provides comfort, which is essential for daily wear. In addition, polycarbonate lenses are known for their impact resistance, ensuring safety in demanding situations.

Unlike traditional lenses, polycarbonate lenses offer UV protection. This feature keeps your eyes safe from harmful rays in sunny conditions. Also, their scratch-resistant coating enhances durability, extending the lifespan of your eyewear. Users often appreciate how easy it is to maintain their clarity. This durability is crucial, especially for safety gear.

However, there are aspects worth considering. Some people may find the optical quality slightly lower than glass lenses. Also, the price can be higher than other options. Despite these minor drawbacks, the benefits of polycarbonate lenses in terms of safety and comfort are undeniable. If you’re looking for versatile eyewear, polycarbonate lenses might be the solution.

Polycarbonate lenses have become increasingly popular in eyewear and safety gear. One major benefit is their incredible impact resistance. Unlike glass, polycarbonate can withstand significant force without shattering. This is crucial in environments where safety is a priority.

In addition to being sturdy, polycarbonate lenses are lightweight. Users often appreciate the comfort during long wear periods. They fit easily into various frames, making them a versatile choice for different styles. However, some might find polycarbonate less scratch-resistant than other materials. This can be a point of concern for many.

Moreover, these lenses offer UV protection, shielding eyes from harmful rays. This feature is essential for outdoor activities. It’s also worth noting that polycarbonate lenses tend to have a lower optical clarity than high-quality glass. This may affect vision for certain users. Balancing these pros and cons is vital in making an informed choice.

Polycarbonate lenses are renowned for their impressive impact resistance. They are made from a high-performance thermoplastic material. This makes them incredibly durable and ideal for safety gear. In tests, polycarbonate lenses withstood significant force without shattering. This is a key factor for eyewear used in high-risk environments.

The data shows that polycarbonate lenses can endure impacts more effectively than traditional glass or plastic lenses. In various applications, they demonstrate 10 times the strength of standard plastic. This level of durability is crucial for athletes, construction workers, and outdoor enthusiasts. Accidental drops or flying debris are common, making strong lenses a necessity.

While polycarbonate lenses offer excellent protection, they also have some drawbacks. They can scratch more easily than other materials. This necessitates careful handling and, sometimes, added coatings that enhance scratch resistance. Finding a balance between protection and potential wear is essential. Maintaining these lenses requires an understanding of their vulnerabilities.

Polycarbonate lenses offer superior impact resistance compared to glass and standard plastic lenses. This chart illustrates the heights from which each material can withstand a drop test, showcasing the robustness of polycarbonate lenses, making them an ideal choice for eyewear and safety gear.

Polycarbonate lenses are gaining attention in eyewear and safety gear. One notable feature is their UV protection capabilities. UV rays can cause serious harm to the eyes. Prolonged exposure may lead to cataracts or other eye disorders. Polycarbonate lenses effectively filter UV light. They typically block 99% of harmful rays. This makes them a popular choice in industries where eye safety is paramount.

Many manufacturers follow strict industry standards for UV protection. They ensure that their polycarbonate lenses meet or exceed safety requirements. However, not all lenses are equal. Some products may lack the necessary UV filtering. Potential buyers should verify certifications when choosing eyewear. A simple label check may not be enough. Not all brands adhere to the same guidelines, leading to confusion.

When using polycarbonate lenses, wearers should consider the environment. Direct sunlight can still pose risks, even with UV protection. Be mindful of reflections from surfaces like water or snow. These can intensify UV exposure. Proper care and maintenance of lenses are crucial too. Scratches or damage can compromise their protective capabilities. Regularly checking lenses is important to ensure full protection.

Polycarbonate lenses are well-known for their lightweight nature. This feature significantly enhances the comfort of eyewear. Unlike traditional glass or plastic lenses, polycarbonate is much lighter. This makes them a popular choice for daily wear. People often forget they have their glasses on.

The comfort of polycarbonate lenses is also due to their design. They are thinner and more flexible, which allows for a better fit. This flexibility can mitigate pressure on the nose and ears. It’s a noticeable difference for individuals wearing glasses for extended hours. However, some might find the lighter feel odd at first. It can take time to adjust.

With increased comfort comes responsibility. Ensuring a snug fit is essential. A poor fit can lead to discomfort despite the lightweight nature. Users may feel the lenses sliding down or pinching the face. Hence, finding the right style and size is key. This simple step can enhance the overall experience with eyewear.

Polycarbonate lenses are often celebrated for their impressive scratch resistance, especially when compared to other materials like glass or standard plastic. When choosing eyewear, the ability to resist scratches is critical. A single scratch can obscure vision and lead to discomfort. Polycarbonate lenses can endure rough handling better than their counterparts. This is particularly beneficial for active lifestyles.

However, not all polycarbonate lenses are equal. Some may still scratch under high stress or harsh conditions. While they are designed to be durable, users must be cautious. Features like hard coatings can enhance scratch resistance. Yet, these coatings may wear off over time, leading to potential vulnerabilities.

In comparison, glass lenses offer superior scratch resistance. However, they are significantly heavier and more prone to breakage. Ultimately, the choice between polycarbonate and alternative materials depends on individual needs. Weight, durability, and vision clarity all play a role. Users should consider their activities and environments when selecting lenses.