A Step-by-Step Guide to Choosing Good Eyeglass Lenses

As an eyeglass lens manufacturer, we want to share our years of experience in the industry and how to distinguish a good lens. As we know, most consumers choose eyeglass lenses as casually as they choose socks. However, the quality of lenses is not like that of socks, where you can tell good from bad just by touch. There is a clear information asymmetry in the quality of lenses. When consumers purchase eyeglass lenses, they rely entirely on the sales assistant's recommendation, often getting confused by a few professional terms.

Seriously speaking, optical design is one of the most critical criteria for optical lenses. Excellent design coupled with perfect execution determines whether the lenses can achieve the expected vision correction effect. However, the specific design principles may not be easily understood by the general public, which is why optical design can easily become a key area for misleading consumers.

I. Lens Analysis

Currently, there are primarily three types of eyeglass lenses on the market: resin, glass, and PC (polycarbonate).

Resin lenses account for the vast majority of the market. Although they look exactly like plastic, they are actually different. In recent years, the raw materials have long been monopolized by foreign companies. Among them, US-based PPG Industries, Japan's Mitsui Chemicals, South Korea's KOC, and SOLUTION are the main suppliers of resin materials.

World-class lens brands we often see, such as Zeiss, Essilor, Nikon, etc., source their materials from Japan's Mitsui. Many glasses priced at only one or two hundred yuan use materials supplied by South Korea's KOC, these lenses can be wholesaled for ten to twenty yuan from small factories in Danyang.

Several core data of lenses: Refractive Index, Abbe Number, Coatings, Aspheric/Spherical Design, and Additional Functions.

1) The refractive index of lenses can be classified as:

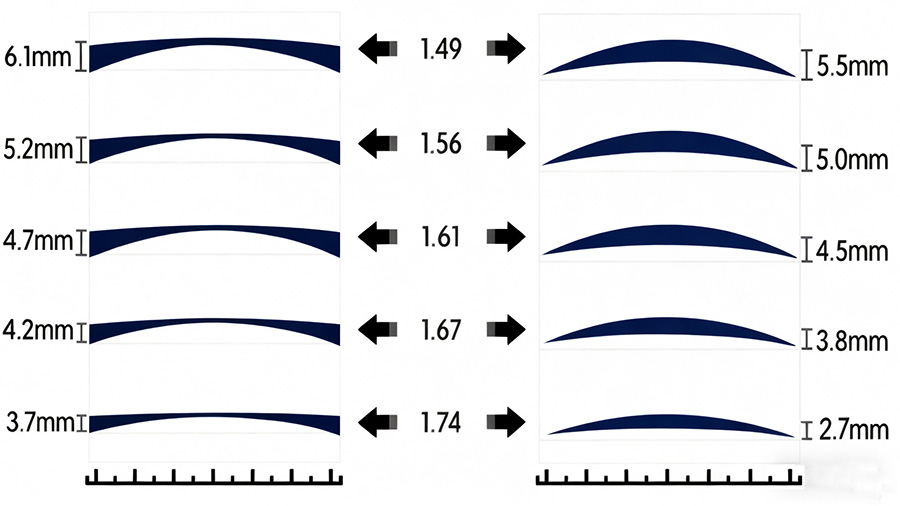

1. 50/1.55/1.60/1.67/1.74. The larger the refractive index number, the thinner the lens (as shown in the graph).

Lens Thickness Comparison

(Using 400 degrees of power for comparison across different refractive indices)

Besides the refractive index, the lens thickness is also affected by the lens size, pupillary distance (PD), and pupil height. Furthermore, whether the frame is full-rim or semi-rimless will also impact the lens thickness.

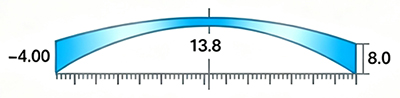

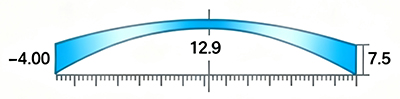

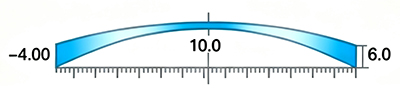

Assuming the lens center thickness is the same for different refractive indices:

For lenses of the same power and material, the higher the refractive index, the thinner the lens edge; conversely, the lower the index, the thicker the edge (as shown in the figure below).

|

1.50 Hardened Resin Lens (Lens Center Thickness 2.0 mm) |

|

1.56 Medium Index Coated Resin Lens (Lens Center Thickness 1.4 mm) |

|

1.61 Ultra-thin Coated Resin Lens (Lens Center Thickness 1.0 mm) |

|

1.67 High Index Coated Resin Lens (Lens Center Thickness 0.9 mm) |

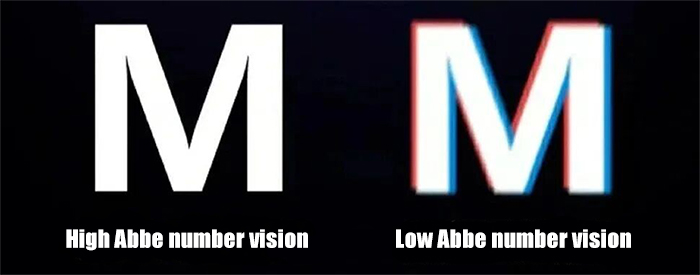

2) The Abbe number of the lens is also one of the influencing factors of lens quality.

The higher the Abbe number, the lower the color dispersion, that is, the smaller the rainbow phenomenon (as shown in the figure below), and the better the optical performance.

| Refractive Index | Features | Abbe Number |

| 1.50 | Thick lens, High Abbe number. Suitable for prescriptions within 200 degrees with no astigmatism. | 58 |

| 1.56 | Thick lens, poor material hardness. Suitable for low prescriptions and full-rim eyeglass frames. | 35.5 |

| 1.60 | Thin lens, high Abbe number. Suitable for most prescriptions, high hardness. | 40.5 |

| 1.67 | Relatively low Abbe number. Choose based on prescription, suitable for medium to high prescriptions. | 31.3 |

| 1.71 | Thin lens, high Abbe number. Suitable for high prescriptions. | 36.2 |

| 1.74 | Extra-thin lens, low Abbe number. Suitable for extra-high prescriptions. | 32.5 |

3) Different refractive indices for resin lenses correspond to different raw materials

1.50 Refractive Index: Mostly made of CR-39, supplied by PPG Industries. It has a relatively high Abbe number, good visual clarity, and clear color, but it is heavier and thicker, prone to oxidation and yellowing, and the lens material is softer. At around 50 ∘C, cracks can appear on the lens surface.

1.56 Refractive Index: The raw material is usually NK55, commonly known as acrylic. It is widely used with a low price. The cheapest wholesale price is only about ten yuan, but it offers weak visual clarity, and the lens is relatively brittle, easily fracturing when drilled for a frame.

1.60 Refractive Index: There are currently two main types on the market: one from South Korea's KOC and one from Japan's Mitsui.

• The Korean one is an acrylic material, which is not strong and easily breaks. Generally, glasses sold on the market, including group-buying platforms, for around one to two hundred yuan use this type of lens.

• The Japanese one is mostly MR-8 polyurethane. It has a higher Abbe number, good visual clarity, and is suitable for rimless (drill-mount) frames. Furthermore, it has high heat resistance, with coating failure only occurring at temperatures of 90∘C.

• So, how do you distinguish between the two materials? Look at the Abbe number: Mitsui Chemicals' raw material has a higher Abbe number of 40.

1.67 and 1.74 Refractive Indices: They are expensive, but they optical performance is generally average. This segment of the market typically targets people with high prescriptions of 500 diopters or more.

II. Coating Analysis

Next, let's talk about lens coatings. Anti-reflective coating was first developed for camera lenses. In the early stages, it couldn't solve the problem of glare. It wasn't until 1950 when Zeiss introduced anti-reflective coatings that the technology developed rapidly. Some people may notice that some eyeglasses lenses reflect light while others do not. This is actually due to the coating. Anti-reflective coating can effectively improve this and achieve a non-reflective effect. But what exactly is a coating? It is the process of adhering thin multi-layers, several hundred nanometers thick (about 1% the thickness of a human hair), onto the surface of the lens. Coating is usually done through physical vapor deposition (PVD) inside a vacuum chamber, which is a process of heating the coating material to its evaporation temperature in a vacuum environment and depositing it onto the lens substrate, similar to how water droplets condense on a piece of glass placed over boiling water.

III. Coating Design

In principle, the more coating layers there are, the better the anti-reflection effect that can be achieved. However, industrialized production involves balancing performance with production cost. Is it more cost-effective to pay ten times the price for 99.9% light transmission or settle for a regular 99% transmittance? To our knowledge, the most commonly design architecture used in the industry is 4 to 7 layers (for the optical layer portion). When the coating layers are within this range, the cost performance is the highest. Although more layers would provide better results, the architectures we usually use now do not include those functional layers, such as waterproof and anti-static.

So, how do you choose lenses with high light transmission? Typically, the brighter the coating reflection, the worse the light transmission. Most eyeglass lenses use a green coating. Blue coatings (not referring to blue-light-blocking lenses) are less common. This is primarily because low reflectivity makes production control much more difficult. It is much like how bright-colored clothing easily shows dirt. Any flaw is immediately visible, leading to poor visual effects. Furthermore, how many people are willing to invest twice the effort (and money) to achieve that final 1% improvement in light transmission quality?

Finally, here are a few key points to summarize for everyone:

1) The higher the refractive index, the thinner the lens. For prescriptions below 600 diopters, a 1.60 index lens is recommended. For prescriptions above 600 diopters, 1.74 is recommended, followed by 1.67.

2) For lens materials, the materials supplied by Japan's Mitsui are recommended as the first choice.

3) The fainter the lens coating, the higher the light transmission. Theoretically, the thicker and more numerous the coating layers, the better; the lens will be relatively more scratch-resistant and waterproof, and other properties will be better.

4) Opting for a reputable brand is advisable.