Polycarbonate lenses have become a leading choice in eyewear today. Their lightweight and impact-resistant nature appeals to many consumers. According to the Vision Council, nearly 40% of eyewear sales in the U.S. include polycarbonate lenses. This is a significant number, highlighting their growing popularity.

These lenses are not only durable but also boast UV protection, making them ideal for outdoor use. In fact, they absorb 100% of harmful UV rays. Yet, despite their advantages, some users report scratches over time. While polycarbonate lenses are strong, they can be prone to lens coating damage.

The demand for polycarbonate lenses continues to rise. As consumers seek quality and value, these lenses often meet their needs. However, some still overlook the importance of proper care. This gap in awareness can lead to dissatisfaction. Addressing these concerns is vital for sustaining the popularity of polycarbonate lenses.

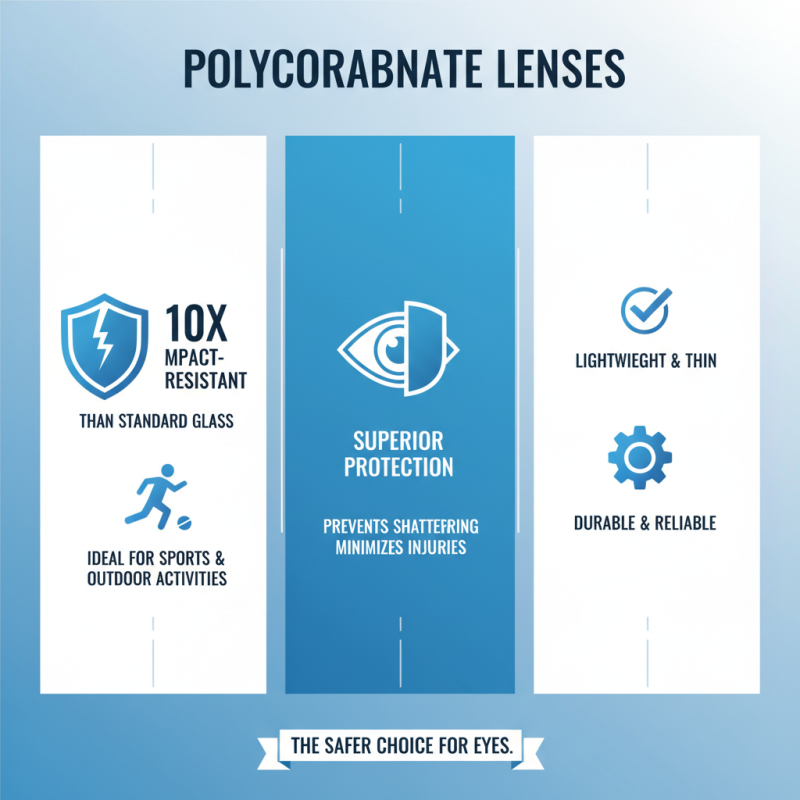

Polycarbonate lenses are a popular choice for eyewear. They are made from a type of plastic called polycarbonate, known for its strength and impact resistance. This material is 10 times more impact-resistant than regular plastic. As a result, polycarbonate lenses are ideal for children and active adults.

These lenses also provide 100% UV protection. This feature is essential for protecting eyes from harmful sun rays. According to the Vision Council, nearly 75% of adults wear prescription lenses, making polycarbonate a practical option. They are lightweight and comfortable. Users often notice they can wear them for longer periods without discomfort.

Tip: When choosing polycarbonate lenses, look for anti-reflective coatings. These coatings reduce glare and improve clarity. Additionally, polarizing options can enhance visual comfort in bright conditions.

While polycarbonate lenses offer many benefits, they may scratch more easily than glass lenses. Regular maintenance is required to keep them clear. Users should handle them carefully and use a proper lens cloth for cleaning. Although polycarbonate is not perfect, it remains a top choice for many.

Polycarbonate lenses are known for their exceptional strength and lightweight nature. The manufacturing process of these lenses involves several key steps that contribute to their popularity. First, polycarbonate material is derived from a unique production method that involves high temperatures and pressure. This results in a material that is durable and impact-resistant, perfect for everyday use.

During the molding stage, the liquid polycarbonate is shaped into the desired lens form. This process requires precision and can sometimes lead to inconsistencies in thickness. If not carefully monitored, these small defects might affect vision clarity. It's worth considering how such imperfections could impact user experience.

After the molding, the lenses undergo polishing and coating processes to enhance clarity and scratch resistance. These coatings are crucial, yet they can sometimes wear off quicker than expected. This can lead to frustration over time.

**Tips:** Always clean your polycarbonate lenses with a microfiber cloth to preserve quality. Store them in a protective case to prevent scratches. Regularly inspect lenses for any signs of wear, as early detection can help maintain their durability.

Polycarbonate lenses are gaining popularity due to their remarkable durability and safety features. These lenses are made from a type of thermoplastic, making them lighter than traditional glass lenses. They can resist scratches and other damages better than many alternatives. This quality makes them ideal for sports and outdoor activities where impacts are possible.

Safety is a crucial aspect of polycarbonate lenses. They provide UV protection, shielding eyes from harmful rays. This is essential for long-term eye health, especially for those who spend much time outdoors. Children’s eyewear often features polycarbonate lenses because they are less likely to shatter. Parents appreciate that they combine protection with comfort.

Tips: When choosing lenses, consider your lifestyle. If you are active, opt for polycarbonate lenses for their impact resistance. Ensure the lenses provide adequate UV protection. Regular maintenance is essential, too. Clean them properly to maintain clarity and prevent scratches. Remember, while these lenses are durable, they still require care.

Polycarbonate lenses have become a significant force in the optical industry. Their lightweight and impact-resistant nature make them ideal for everyday eyewear. Unlike traditional lenses, they cater to those seeking durability without extra weight. This combination appeals to many, particularly active individuals.

Market trends indicate a growing demand for polycarbonate lenses. They are favored in sports and safety eyewear. Their ability to withstand sudden impacts makes them vital in intense environments. Additionally, advancements in technology have improved the clarity and scratch resistance of these lenses. Yet, some consumers still grapple with the price, as polycarbonate options can be more expensive than alternatives.

While polycarbonate lenses are gaining traction, there are areas for improvement. Some users find them prone to scratching, despite advancements. Regular wear and tear can lead to diminished clarity over time. Increasing awareness about proper care could enhance user experiences. The ongoing development of even more resilient materials could further revolutionize the industry.

| Attribute | Details |

|---|---|

| Material | Polycarbonate |

| Type | Plastic lenses |

| Impact Resistance | High |

| Weight | Lightweight |

| UV Protection | Yes, blocks harmful UV rays |

| Optical Clarity | Excellent |

| Scratch Resistance | Moderate (can be improved with coatings) |

| Applications | Eyewear, safety goggles, sports glasses |

| Popularity Reasons | Durability, lightweight, and UV protection |

| Market Growth Rate (2023) | Approx. 5% annually |

Polycarbonate lenses are gaining traction due to their unique properties. They offer high impact resistance, making them ideal for sports and outdoor activities. According to industry reports, polycarbonate lenses are 10 times more impact-resistant than standard glass. This resistance helps prevent shattering and minimizes potential injuries.

When comparing polycarbonate to other lens materials, several factors come into play. For example, glass lenses provide optical clarity but lack durability. CR-39 lenses are lighter than glass but not as strong as polycarbonate. Data indicates that polycarbonate lenses are favored by 75% of active lifestyle consumers. This statistic underscores their popularity and practicality.

Tips: Always consider your lifestyle before choosing lenses. If you engage in sports, polycarbonate is the way to go. Regular wearers should also think about UV protection. Despite their advantages, polycarbonate lenses may scratch easily. Invest in a scratch-resistant coating to enhance their longevity. Seek advice from an optometrist to ensure you make the right choice.